-

Vetro fuso a serbatoi di acciaio (469)

-

carri armati di acciaio inossidabile (434)

-

La fusione ha legato i carri armati a resina epossidica (469)

-

Serbatoi in acciaio galvanizzato (321)

-

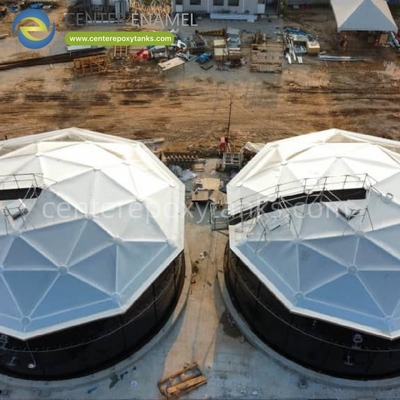

Tetti di alluminio della cupola (1257)

-

Serbatoi di stoccaggio delle acque reflue (226)

-

serbatoi di acciaio saldato (457)

-

Contenitori a pressione (295)

-

Digestore anaerobico (201)

-

Serbatoi di acqua industriali (349)

-

Serbatoi in acciaio rivestiti di vetro (180)

-

Serbatoi di acciaio serrati (345)

-

Serbatoio del fango (115)

-

Serbatoio del biogas (173)

-

Serbatoi di stoccaggio di lixiviazione (133)

-

Serbatoi di stoccaggio dell'acqua agricola (179)

-

Serbatoio dell'acqua di fuoco (166)

-

Silos di stoccaggio del grano (146)

-

Progetti di biogas (381)

-

Progetti di trattamento delle acque reflue (270)

-

Tetti a doppia membrana (223)

|

Informazione dettagliata |

|||

Descrizione del prodotto

Tetto a cupola in alluminio per serbatoi di stoccaggio industriali: una copertura versatile e leggera per materiali industriali

Il moderno panorama industriale si basa fortemente su serbatoi di stoccaggio robusti ed efficienti per contenere una vasta gamma di materiali, inclusi liquidi, fanghi e solidi sfusi secchi. La scelta di una copertura adatta per il serbatoio è una decisione critica che influisce sulla qualità dei materiali, sull'efficienza operativa e sulla conformità ambientale. Le coperture tradizionali, spesso realizzate con materiali pesanti come l'acciaio, possono essere difficili da installare, costose da mantenere e richiedono supporti interni che ostacolano l'accesso. Questi svantaggi hanno generato la necessità di una soluzione più versatile e leggera. I tetti a cupola in alluminio sono emersi come la scelta principale, offrendo un'alternativa superiore che fornisce una copertura durevole, affidabile e facile da installare per una vasta gamma di materiali industriali.

Caratteristiche e vantaggi del prodotto

Il design di un tetto a cupola in alluminio è una testimonianza della potenza dell'ingegneria geodetica. Questi tetti sono costruiti con pannelli in alluminio leggeri e ad incastro che formano una cupola robusta e autoportante. L'esclusiva geometria distribuisce i carichi in modo efficiente, consentendo alla struttura di coprire ampi diametri senza la necessità di ingombranti colonne interne. Questo è un vantaggio chiave per i serbatoi industriali, in quanto lascia l'interno del serbatoio completamente libero, semplificando le procedure di ispezione e manutenzione. La natura leggera dell'alluminio riduce anche in modo significativo il carico strutturale sulle pareti del serbatoio, rendendolo una soluzione ideale sia per le nuove installazioni che per l'adeguamento di serbatoi esistenti.

La scelta dell'alluminio come materiale principale offre diversi vantaggi chiave per le applicazioni industriali. L'alluminio ha la naturale capacità di formare uno strato di ossido passivo e protettivo che lo rende altamente resistente alla ruggine e alla corrosione. Questa eccezionale durata garantisce una lunga durata con una manutenzione minima, un fattore cruciale nell'esigente ambiente industriale. I pannelli in alluminio sono meticolosamente sigillati per creare una barriera impermeabile, sia a tenuta stagna che ermetica, fornendo una protezione completa per il contenuto del serbatoio.

Uno dei vantaggi più significativi di un tetto a cupola in alluminio è la sua versatilità. Gli stessi principi di progettazione che proteggono l'acqua e le sostanze chimiche possono essere applicati ai materiali sfusi secchi, fornendo una tenuta completamente impermeabile contro pioggia, neve e detriti trasportati dal vento. Questa capacità di proteggere una vasta gamma di materiali rende il tetto a cupola in alluminio una soluzione flessibile ed economicamente vantaggiosa per molteplici applicazioni industriali. Il design sigillato aiuta anche a contenere fumi preziosi o pericolosi, fornendo un ambiente di stoccaggio più sicuro e controllato e garantendo la conformità alle severe normative ambientali.

L'economicità intrinseca del tetto a cupola in alluminio è un altro importante vantaggio. La natura leggera e il processo di installazione semplificato riducono i costi complessivi del progetto. La lunga durata, unita ai minimi requisiti di manutenzione, ne aumenta ulteriormente la proposta di valore a lungo termine, rendendolo un investimento saggio per qualsiasi operazione industriale.

Applicazioni del prodotto

Sebbene i tetti a cupola in alluminio siano una soluzione ideale per lo stoccaggio industriale generale, i loro vantaggi unici li rendono applicabili a una vasta gamma di altri scenari di stoccaggio in cui la protezione e l'integrità sono fondamentali.

Per la gestione dell'acqua e delle acque reflue, questi tetti sono ampiamente utilizzati su serbatoi di acqua potabile, impianti di trattamento delle acque reflue industriali e impianti fognari urbani. Garantiscono la purezza dell'acqua e impediscono il rilascio di odori dannosi o sgradevoli.

Nell'stoccaggio di materiali sfusi secchi, sono una scelta affidabile per i serbatoi silo utilizzati per lo stoccaggio di cereali, minerali e altri materiali che devono essere protetti dall'umidità e dagli agenti atmosferici.

Nell'industria petrolchimica, i tetti a cupola in alluminio vengono utilizzati su serbatoi che immagazzinano petrolio greggio o altri liquidi volatili dove sono necessari il controllo dell'evaporazione e un ambiente sigillato a prova di esplosione. Allo stesso modo, per i serbatoi di stoccaggio di prodotti chimici, un tetto a cupola offre un'opzione resistente alla corrosione e leggera per il contenimento di vari prodotti chimici.

Vantaggi dell'azienda

Il nostro impegno per la qualità e l'eccellenza ingegneristica è ciò che ci distingue nel settore dei serbatoi di stoccaggio. Utilizziamo un processo di produzione altamente efficiente che è verificato e certificato in modo indipendente secondo gli standard internazionali, tra cui ISO 9001 e EN1090. Questo assicura che ogni componente sia prodotto con il massimo livello di precisione e controllo qualità.

Offriamo un Servizio a Catena Completa che supporta i clienti in ogni fase di un progetto, dalla consulenza iniziale e progettazione personalizzata alla produzione, all'installazione in loco e al supporto post-vendita globale. Questo approccio integrato garantisce una tempistica del progetto fluida ed efficiente e garantisce un prodotto finale durevole e ad alte prestazioni. Il nostro dedicato team di ricerca e sviluppo è in costante innovazione, lavorando per far progredire la nostra tecnologia e la scienza dei materiali per soddisfare le esigenze in evoluzione dei nostri clienti. La nostra vasta esperienza, con progetti che attraversano continenti e diverse applicazioni, ci consente di fornire soluzioni su misura e affidabili anche per le sfide più complesse.

Casi studio aziendali

I seguenti casi illustrano la nostra capacità di fornire soluzioni affidabili ed efficaci in una vasta gamma di applicazioni. Sebbene i serbatoi stessi non siano destinati allo stoccaggio industriale generale, mostrano la profonda esperienza della nostra azienda nella fornitura di sistemi di contenimento robusti per vari settori, inclusi progetti municipali, industriali e agricoli su larga scala. Ogni caso evidenzia il nostro impegno a fornire soluzioni su misura che soddisfano le esigenze specifiche del cliente in termini di volume e durata.

Progetto idrico municipale dell'Ecuador

Per un progetto idrico municipale in Ecuador, abbiamo fornito un serbatoio per supportare l'infrastruttura di una città. Questo progetto ha coinvolto 1 serbatoio con una capacità totale di 1.023 metri cubi, dimostrando la nostra capacità di soddisfare le rigorose esigenze della gestione delle acque urbane con una soluzione affidabile.

Progetto di approvvigionamento idrico rurale di Cuba

Abbiamo fornito una soluzione per un progetto di approvvigionamento idrico rurale a Cuba. Questa installazione consisteva in 2 serbatoi con una capacità totale di 2.249 metri cubi, fornendo una fonte d'acqua fondamentale e affidabile per più villaggi in un ambiente difficile.

Progetto di acqua potabile in Thailandia

Abbiamo fornito un serbatoio per un progetto di acqua potabile in Thailandia. Questa installazione includeva 1 serbatoio con una capacità totale di 1.210 metri cubi, evidenziando la nostra capacità di fornire una soluzione su misura per un'esigente utenza pubblica.

Conclusione

Un tetto a cupola in alluminio è un componente fondamentale per uno stoccaggio industriale efficace. Fornendo una barriera sigillata, leggera e incredibilmente durevole, questi tetti offrono una protezione superiore per una vasta gamma di materiali. La loro versatilità, combinata con la facilità di installazione e i minimi requisiti di manutenzione, li rende una scelta economica e affidabile per qualsiasi operazione industriale. Il nostro impegno a fornire soluzioni affidabili e di alta qualità, supportate da una vasta esperienza e da una gamma completa di servizi, assicura che ogni operazione possa beneficiare della protezione superiore e della tranquillità che un tetto a cupola in alluminio offre.